SEPLITE® CT101

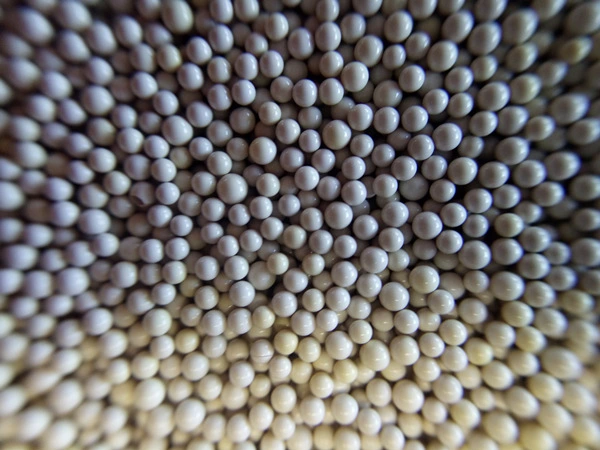

SEPLITE® CT101 is the solid strong acid catalyst for the production of MTBE (methyl tertiary-butyl ether) with the usage of sulfonic acid groups based on the matrix of styrene-DVB copolymer to form the proper pore structure. The technical performance of this polymeric catalyst have reached advanced level with its important features of high activity and long service lifetime.

SEPLITE® CT101 Catalytic Resins Keyfeaturesand benefits:

-

High total capacity, high conversion rate, and long catalyst lifetime

-

Proper pore structure, high sensitivity, good low-temperature activity

-

Excellent thermal tolerance and stability

-

Production adopted by full-automatic control system to guarantee the stable quality

SEPLITE® CT101 Catalytic Resins PhysicalandChemical Characteristics:

| Ionic form | H+ |

| Functional group | Sulfonic acid |

| Matrix | Crosslinked polystyrene |

| Physical appearance | Brown Porous opaque beads |

| Total Capacity mmol/g [H+] | ≥5.2 |

| Water retention % | 50--58 |

| Shipping weight g/ml | 0.74—0.84 |

| Density g/ml | 1.15—1.25 |

| Particle size mm,% | (0.35—1.25)≥95 |

| Whole beads count % | ≥95 |

| Uniformity coefficient | <1.6 |

| Average pore size nm | 35-48 |

| Surface area m2/g | 32--59 |

| Pore volume ml/g | 0.30—0.45 |

| Maximum Operating temperature ℃ | 120 |

| Recommended storage temperature ℃ | 1-40 |

SEPLITE® CT101 Catalytic Resins Recommended Operating Conditions:

1. Metal ions and alkaline substance content ≤2ppm, butadiene content≤0.1%

2. Alcohol and olefin ratio 0.98-1.05 : 1

3. Reaction temperature 50-80℃

4. Pressure drop limitation ≤0.1Mpa across the bed

SEPLITE® CT101 Catalytic Resins Precautions:

Resins should be stored in sealed containers or bags where temperature was above 0℃ in dry conditions without exposure to direct sunlight.

Do not mix ion exchange resin with strong oxidizing agents; otherwise it will cause violent reactions.

In case of eyes contact with resins, rinse eyes immediately with plenty of water, and consult a specialist. Material and samples must be disposed according to local regulations.

Dry polymers will expand when become wetted and may cause an exothermic reaction. Spilled materials may be slippery.

SEPLITE® and Monojet™ are registered trademarks of Sunresin New Materials Co. Ltd., Xi`an

This information is general information and may differ from that based on actual conditions. For more information about SEPLITE® resins, please contact SUNRESIN® directly.